| Technology | Description |

|---|---|

Clip Bonding

|

Clip-bonding technology replaces the standard wire-bond connection between die and lead by a solid copper bridge, soldered by solder paste, which offers unique package resistance, better thermal resistance, and ultra-fast switching performance due to the small package. |

Ultra Sonic Welding

|

In order to weld copper, heat, and pressure are applied to the two pieces of metal that are being joined together. The heat melts the metal, which allows it to flow and be shaped into the desired joint. The pressure then holds the joint in place until it cools and solidifies. |

| Products | POD & Description |

|---|---|

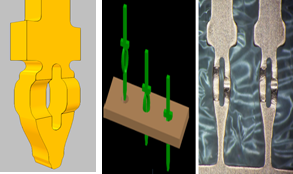

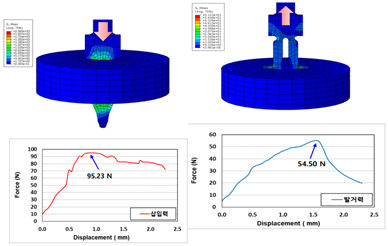

Press Fit

|

The press-fit technology utilizes press-fit pins to establish the module contacts to the printed circuit board. The basic principle is the bigger latitude of the press-in zone than of the PCB hole. This technology ensures easy and fast mounting of the module and PCB, reducing assembly time and cost by eliminating the solder process. |

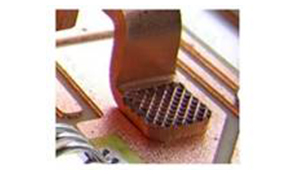

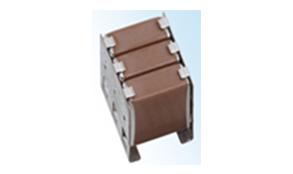

High Cap Stacked MLCC

|

Multilayer Ceramic Capacitor (MLCC) works as a 'dam' that temporarily charges and discharges electricity. It regulates the current's flow in a circuit and prevent electromagnetic interference between components. |

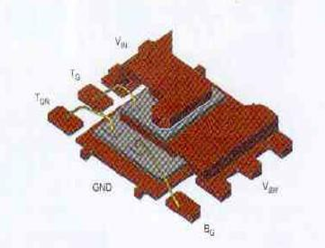

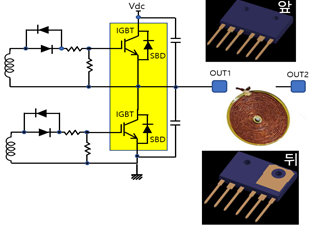

IH System 3.5KW

|

Coupled Power Package applied to IH system with WBG Power Device |